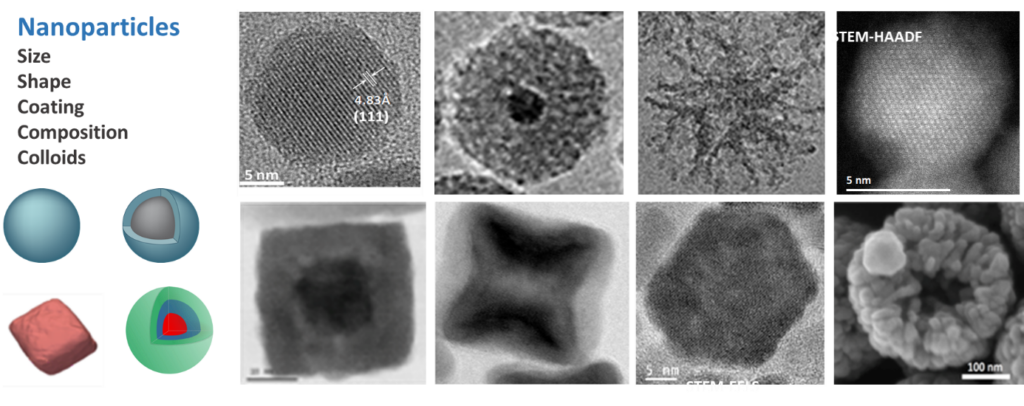

Our nanoparticle (NP) design is based on well-established and fundamental mechanisms of nucleation and growth. The various types of reactions used to design our NPs include thermal decomposition, hydrothermal route, sol-gel synthesis, reduction, etc… The NPs are either formed in a single phase structure (ferrite, gold or silica) or as a multi-component nanostructures (bi-magnetic NPs, doped NPs, ferrite@silica NPs).

Three examples of chemical strategies for NP design are presented :

1) Mastering the size, shape and composition of IO NPs by the controlled design of precursors

2) Magnetic core-shell and onion type magnetic NPs

3) Engineering of multi-compartment silica nanoplatforms

- Mastering the size, shape and composition of iron oxide nanoparticles by the controlled design of precursors and the understanding of the thermal decomposition process

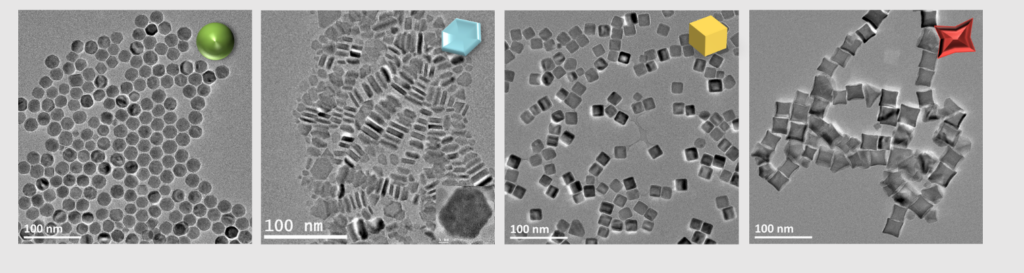

Home-made iron stearates, FeSt2 and FeSt3, allow a reproducible synthesis of 10 nm sized iron oxide nanoparticles (IONPs) but only FeSt3 allows synthesizing IONPs with mean size higher than 15 nm. Anisotropic IONPs can be synthesized by introducing shape driving ligands such as sodium oleate or by-products resulting from thermal decomposition of benzylether. By adjusting the nature of iron stearate, the nature of surfactants and the heating rate: different shapes were obtained.

A. Impact of the iron stearate precursor FeSt2 or FeSt3 on the size and shape of iron oxide NPs.

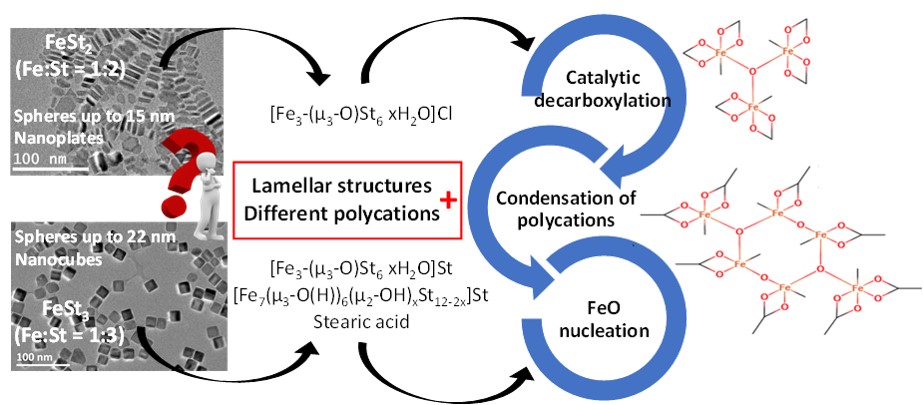

- Determination of the lamellar structure and polynuclear based composition of FeSt2 and FeSt3 precursors which are iron precursors in the well-known thermal decomposition synthesis method of iron oxide NPs

- Explaining the NP synthesis differences between FeSt2 and FeSt3 by the presence of bigger polynuclear complex in FeSt3

- Elucidating the formation mechanisms of polynuclear complexes by considering hydrolysis and condensation rates within the iron (III) or (II) chloride solutions

- Revealing a nucleation mechanism of iron oxide NPs by condensation of activated complexes

B. Study of the composition of nuclei in our thermal decomposition process

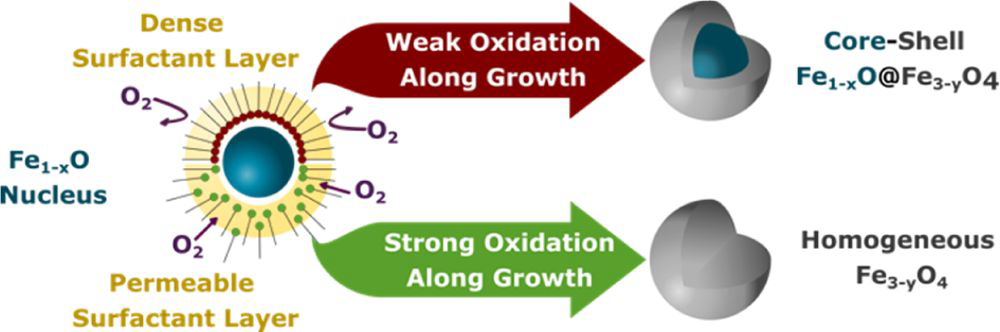

The nuclei composition in the thermal decomposition process is wüstite Fe1-xO. The presence in iron oxide NPs of oxide defects and composition results from a competition between growth and oxidation kinetics of preformed wüstite nuclei. The dense monolayer of surfactants at the nuclei surface hampers nanoparticle oxidation. The oxide composition is controlled by heating rate & solvent and surfactant natures.

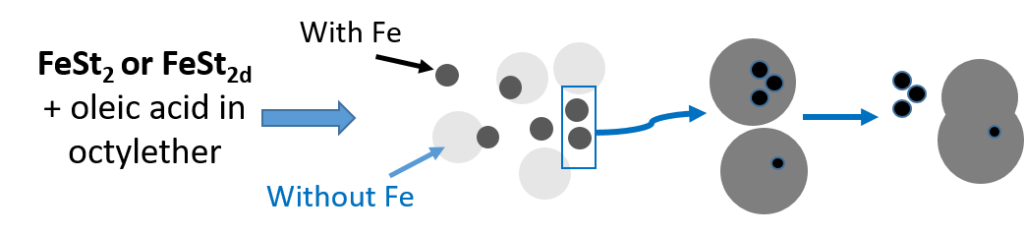

C. Unveiling the nucleation mechanism of IONPs: first evidence of a confined nucleation in nanostructures in organic media which explains why the nucleation and growth steps are well separated in the thermal decomposition process

2. Magnetic core shell/ onion type NPs

3. Engineering of multi-compartment silica nanoplatforms

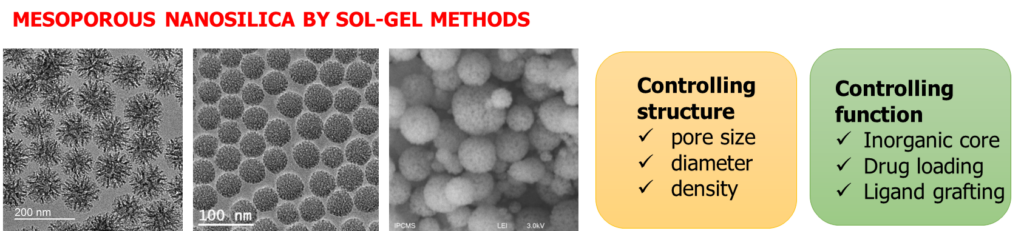

Another strategy of functional NPs developped in our team concerns the design of engineered silica nanoplatforms. Starting from various mesoporous silica synthesis, we developped new multi-compartment silica nanoplatforms with a great control over structures or the functionalization.

Three examples of hierarchical MS assemblies are presented here

- Modulation of the silica structure morphology around IO NPs

- Orienting the pore morphology of core-shell magnetic mesoporous silica with the sol-gel temperature

- Engineering of silica shell around carbon-based material

A. Modulation of the silica structure morphology around IO NPs

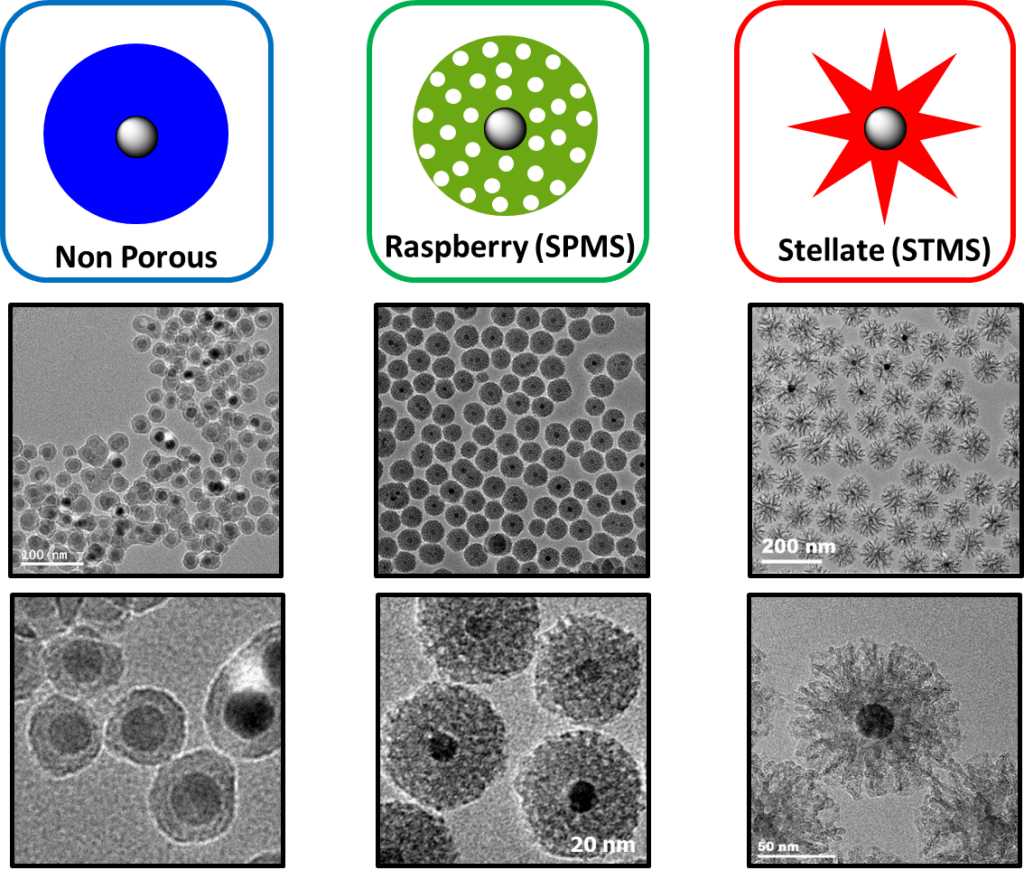

In this work, we applied three complementary synthesis protocols of silica shell around IO NPs (ca. 17 nm size, synthesized by thermal decomposition). The silica shell structure and morphology (non porous vs porous; pore size, shell thicknesses) depend strongly on the reaction conditions and the surfactants used.

B. Orienting the Pore Morphology of Core-Shell Magnetic Mesoporous Silica with the Sol-Gel Temperature

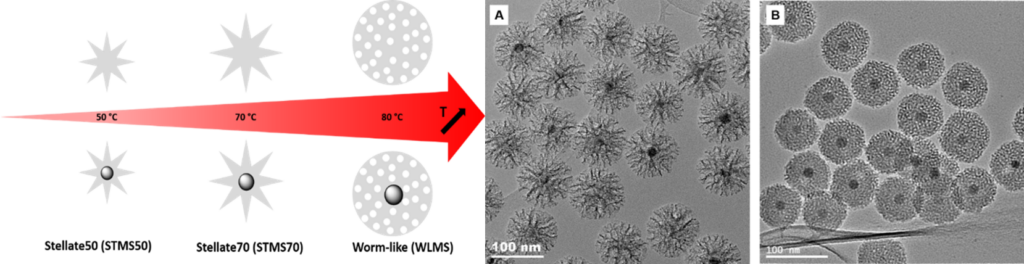

Tailoring the MS structure (such as surface area, pore morphology) through simple experimental conditions is highly relevant for an easy implementation. In this work, the sol-gel reaction temperature (Tsg) was reported as a key parameter to tune pore morphology of MS NPs. The pore morphology of free core MS NPs or iron oxide NPs coated with MS shell was found here to be easily oriented either towards stellar (ST) or a worm-like (WL) morphology depending on the temperature range.

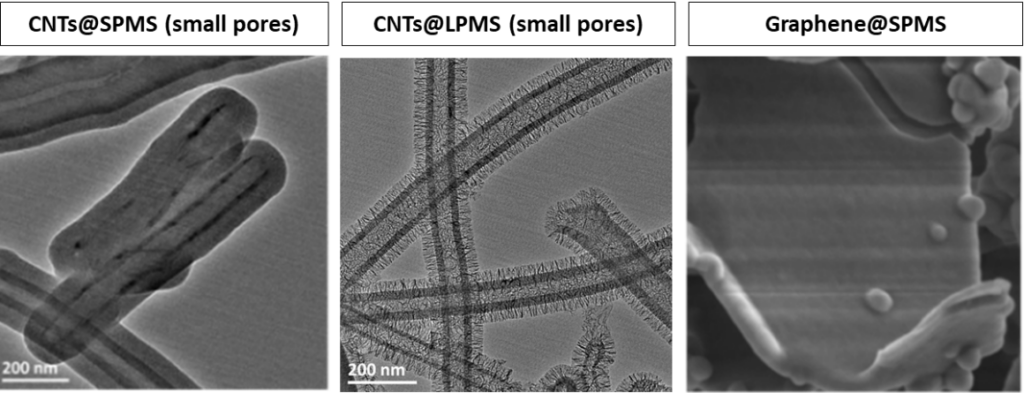

C. Engineering of silica shell around carbon-based materials

Previous strategies of MS shell coating were also applied to carbon based materials (such as carbon nanotubes or few layer graphene). This method involves the phase transfer of hydrophobic carbon and then the surfactant driven sol gel condensation to achieve controlled pore morphology.