Diversity of the magnetic coupling behaviors in the CoFe2/CoFe2O4 system N. Viart, R. Sayed Hassan, C. Mény, P. Panissod, C. Ulhaq-Bouillet, J. L. Loison, G. Versini, F. Huber, and G. Pourroy Appl. Phys. Lett. 86, 192514 (2005)

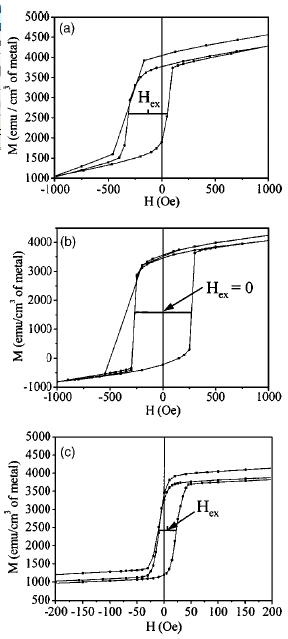

The CoFe2/CoFe2O4 system has been considered for use as hard electrodes in spin valve devices. In this letter, we focus on the nature and intensity of the magnetic exchange coupling between the two phases. CoFe2/CoFe2O4 and CoFe2O4/CoFe2 bilayers were fabricated by pulsed laser deposition from a metallic CoFe2 alloy target in a vacuum and in an O2/N2 oxidizing atmosphere for the metallic and oxide layers, respectively. Depending upon the elaboration conditions, three different coupling behaviors have been observed : Ferromagnetic, biquadratic, and antiferromagnetic. The minor loop shift and the apparent coercive field of the metal observed in the first two cases are of several hundreds of Oe for a metal thickness of 10 nm. Those very large loop shifts and coercive fields confirm the potential usefulness of this system in terms of applications.

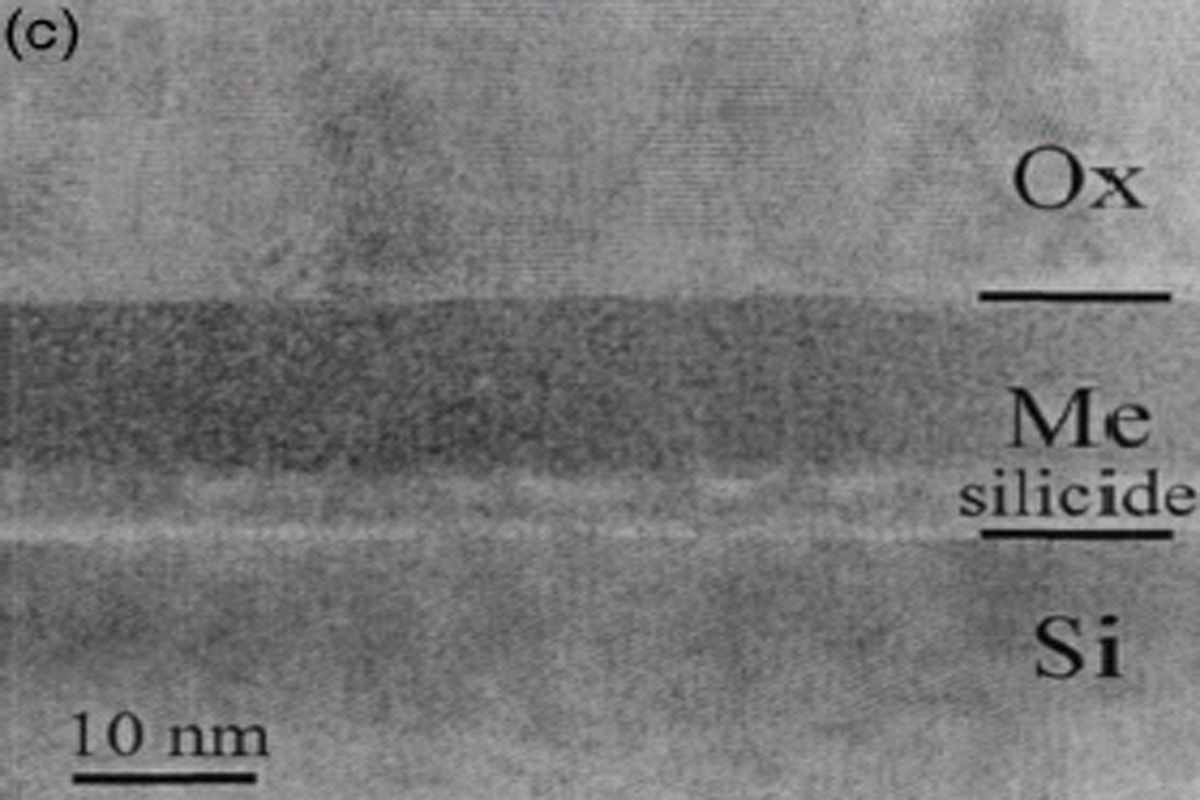

Three different deposition procedures were used : (a) The oxide was deposited first by ablating the metallic target in 6.7 Pa of O2/N2. The laser was then stopped and the deposition chamber pumped down to a background pressure of 1.3×10−3 Pa. The laser was then turned on again for the deposition of the metal. (b) The metal was deposited first, in a vacuum (1.3x 10−3 Pa). The laser was then stopped and turned on again only when the 6.7 Pa O2/N2 pressure was reached for the deposition of the oxide. (c ) The metal was deposited first as previously, but the laser was not stopped during the establishment of the O2/N2 pressure necessary for the deposition of the oxide. Hysteresis loop of a bilayer deposited under condition (a), recorded at room temperature. Bilayers deposited under (b) and (c ) conditions show similar shapes.

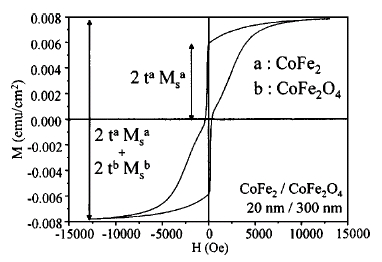

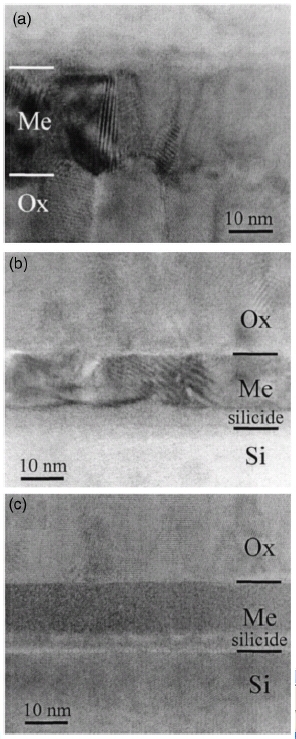

Transmission electron microscope observations of bilayers.

Minor loops of samples deposited under the three different conditions : (a) CoFe2(300 nm)/CoFe2O4(20 nm), (b) CoFe2(12 nm)/CoFe2O4(300 nm), and (c ) CoFe2(15 nm)/CoFe2O4(300 nm).