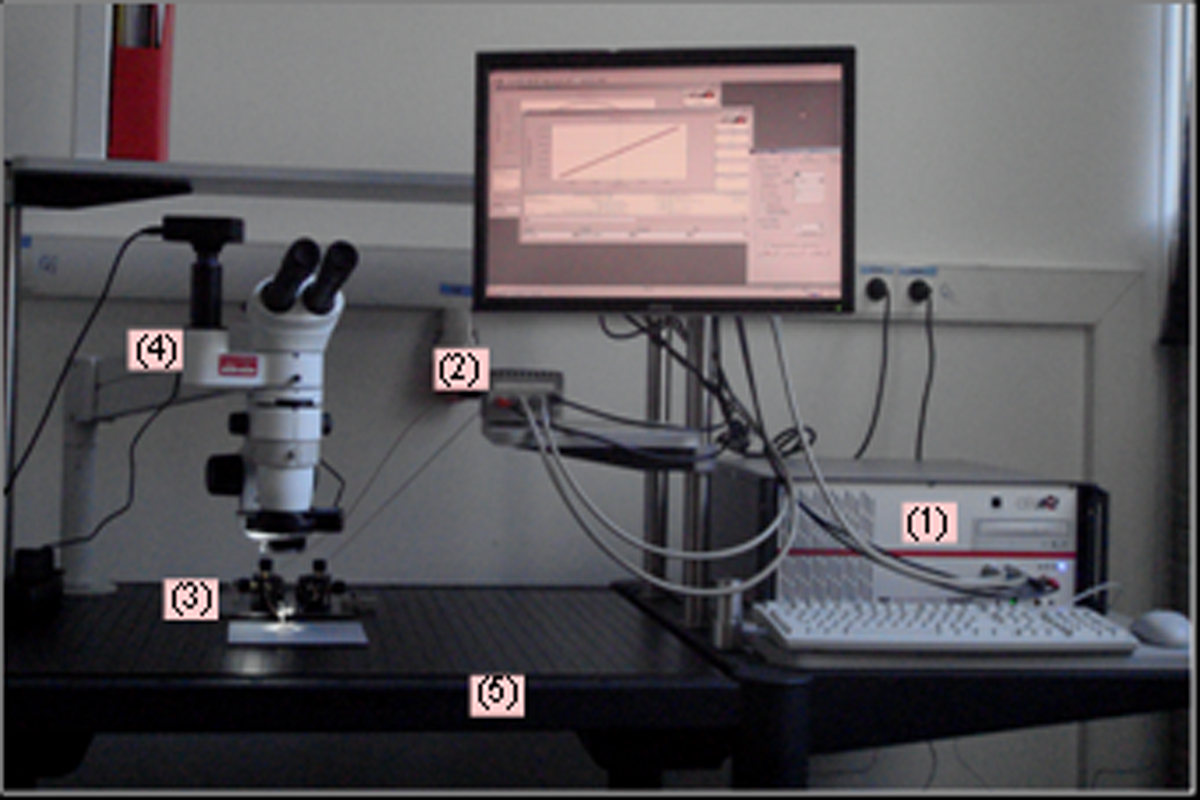

Polarization switching processes in ferroelectrics and magnetoelectrics are of central importance in basic and applied research areas. The most characteristic macroscopic phenomenon representing this process is the hysteresis loop, i.e., the hysteretic dependence of the order parameter on the conjugate force, such as P(E) dependence in ferroelectrics. Such integral measurements provide fundamental information on the overall switching process. This is usually the first step in the characterization of ferroic capacitors.P(E) loops are generally integrated from the current or charge variations in the ferroelectric sample induced by an external voltage, often applied between the sample and a reference capacitor connected in series. Such basic circuit is referred to as Sawyer-Tower circuit. Nowadays, modified electronic schemes are proposed to eliminate parasitic impedances and back-switching processes that accurse in the classical Sawyer-Tower circuit. An alternative scheme in which the sample is grounded during the switching process is now widely used in modern ferroelectric testers. This so-called virtual ground method is especially adapted for high-precision ferroelectric measurements and it used as integral part of the commercial aixACCT measurement system available in our laboratory.The aixACCT TF-Analyzer2000 at IPCMS provides several standard measurement modes such as: Dynamic and static P(E) hysteresis measurements; fatigue, retention and imprint measurements; leakage current and C(V) measurements. More “exotic” measurements are also offered by our setup when combining the TF-Analyzer2000 to (magneto)-optical and microscopy methods. This combination is highly suited for the study of time-resolved switching processes (frequency and pulse-dependent measurements) and crossed P-M magnetoelectric measurements.TF-Analyzer2000 (Basic unit(1) and FE-Module(2)). (3) Probe station equipped with two micro- positioners with a pivot head and x, y, z movements allowing the electrical contact of microstructures as small as 5 m. The microprobes are aligned on the probing pads by using a stereomicroscope (4) allowing ergonomic viewing posture with long working distance and a wide zoom range allowing an magnification up to 80x at an effective working distance of 8 cm. The whole system is placed on a mobile modular anti-vibration workstation (5) designed for vibration-sensitive imaging and optical applications.

Electric measurements