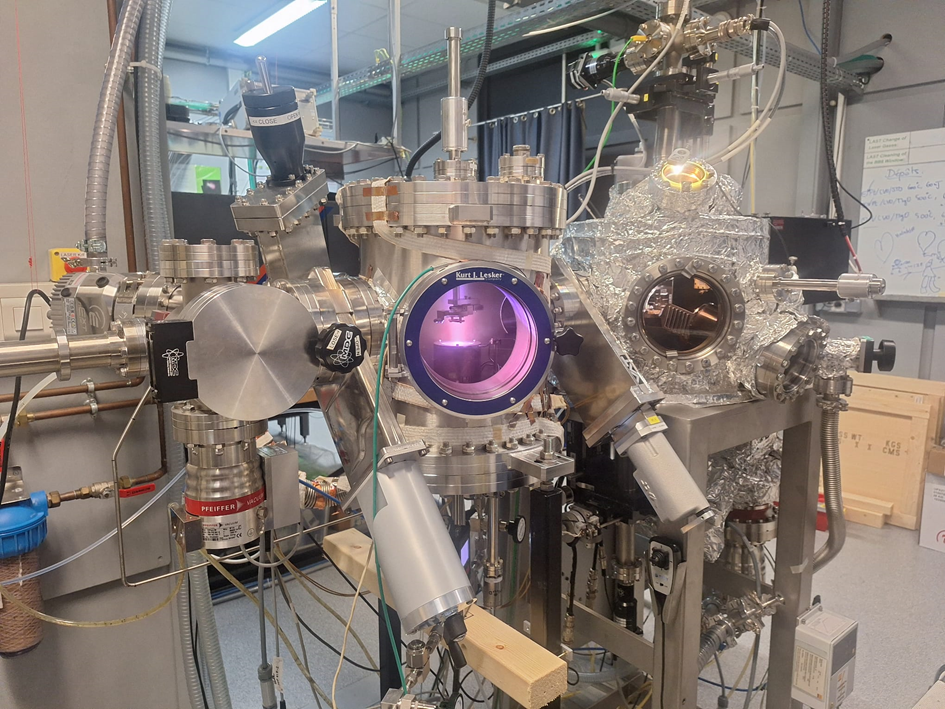

The sputtering chamber, directly connected to one of the two PLD chambers, enables successive depositions without intermediate venting. The sputtering system, assembled by the platform team, was custom-built to fit perfectly with the PLD configuration. It is equipped with a 2” DC magnetron, enabling, among other things, the deposition of metallic materials (platinum, copper, etc…) which, combined with the functional oxides developed by the “thin-film oxides” team, allows studies in the field of spintronics.

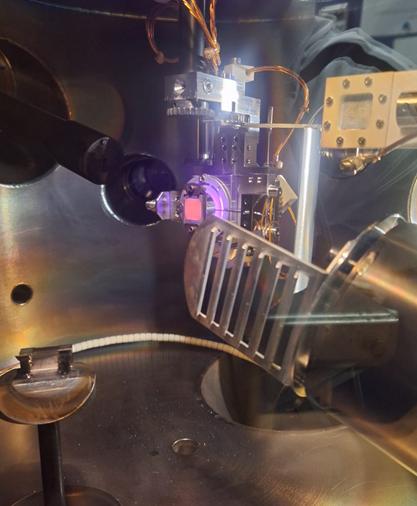

The platform has also improved the heating of the pulsed laser deposited samples. In addition to the existing resistive heating system, a new laser heating system has been installed. This new heating system heats the back of the sample holder using a laser (class 4) with a wavelength of 980 nm. The temperature is measured at the rear with a pyrometer. With this new device higher temperatures can be reached (at least 1100°C compared to 900°C for the resistive heating). Temperature changes can be more rapid, and annealing in an oxygen atmosphere is feasible, since laser heating eliminates issues like thermal inertia and contact oxidation.

For more information on these two new pieces of equipment, jointly funded by PEPR SPIN, CNRS, IPCMS and the “Thin-Film Oxides” team, please contact one of the PLD platform members.