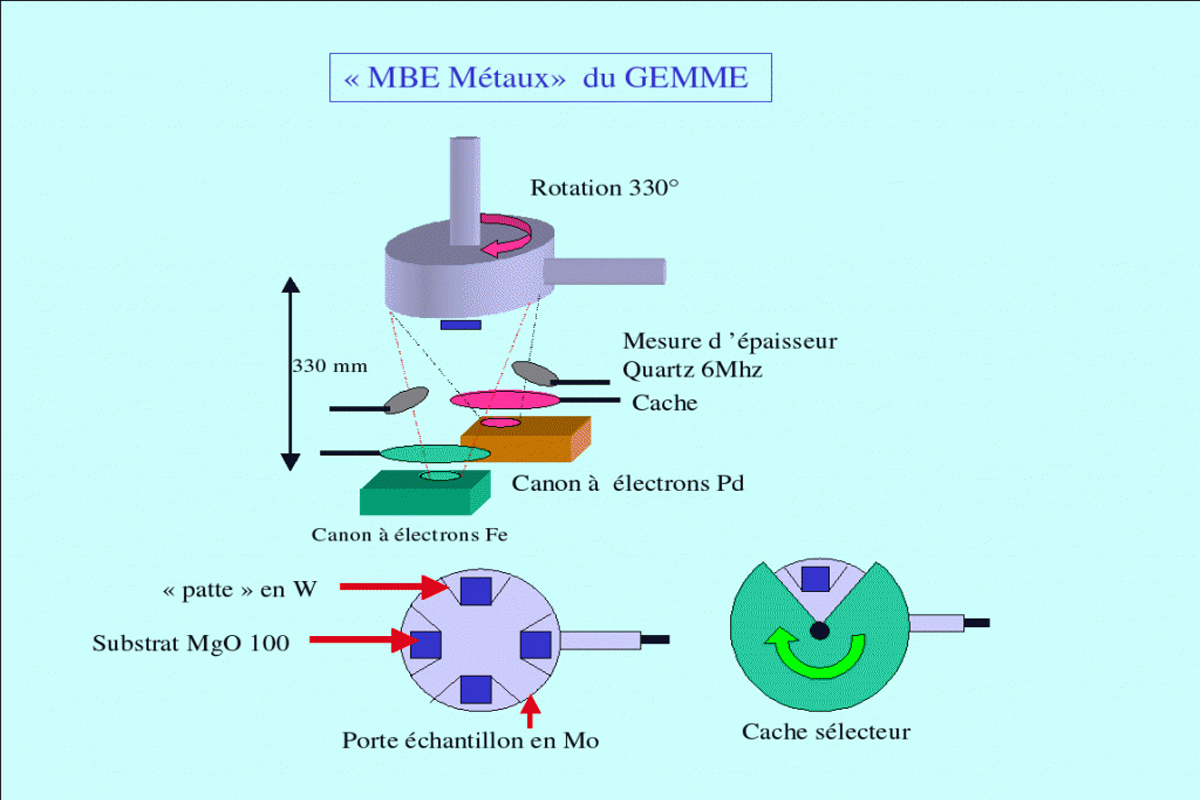

The DMONS group has a built evaporation of metals under UHV dedicated manufacturing artificial structures as multi-layer superlattices alternating monocrystalline layers of magnetic metals (Co, Fe , Ni, Gd … ) and those of

“>nonmagnetic ” spacers ” (Ru , Mn , Cu, … ) , and for the manufacture , by co- evaporation , thin layers of binary alloys ( CoPt , FePd … ) .

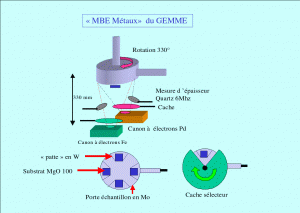

This stand is equipped with two electron guns , with 4 Crucible barrel. A power and 10 kilowatts HT Scanning beam allow evaporation of all metals . A substrate 4 ” where several smaller substrates ( max 12 ) , can be prepared in one operation , through a switch cover .

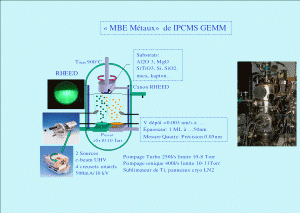

The deposition temperature is dangling programmable up to 950 ° C in vacuo . The deposition rate is programmable from 0.005 nm / s to greater than 0.2 nm / s values. The continuous rotation of the sample holder plate improves the uniformity of deposition.

The crystalline quality of the samples is controlled in situ diffraction of fast electrons ( RHEED ) . A tracking system layer by layer growth via RHEED oscillation is available. The thickness of the deposits is controlled by quartz balances . A new manipulator is equipped with a tilt from 0 to 40 °.

The main topics of study relate systems giant magneto- resistance and magneto- resistance tunnel , dynamic ultrafast magnetization , the magnetization processes in magnetic nanostructures ( son of epitaxial cobalt , pads CoPt ) and correlations structural properties / properties in anisotropic magnetic alloys ( CoPt3 , CoPt , FePd …

Operation of the molecular beam epitaxy in the institute

Sample-holder of the molecular beam epitaxy in the institute

The MBE chamber is connected by a UHV common lock to a chamber which allows dry ion etching part means for generating magnetic nanostructures and epitaxial magnetic nanostructures

Contact :