The elaboration of multilayered materials using sputtering has many applications: materials for high density magneto-optic storage media as compact disks for instance. This technique also allows the preparation of complex devices that combine memory elements (magnetic junctions with simple tunnel effect) and diode elements (double tunnel junctions). In addition, the growth of all kinds of layers can be studied using sputtering.

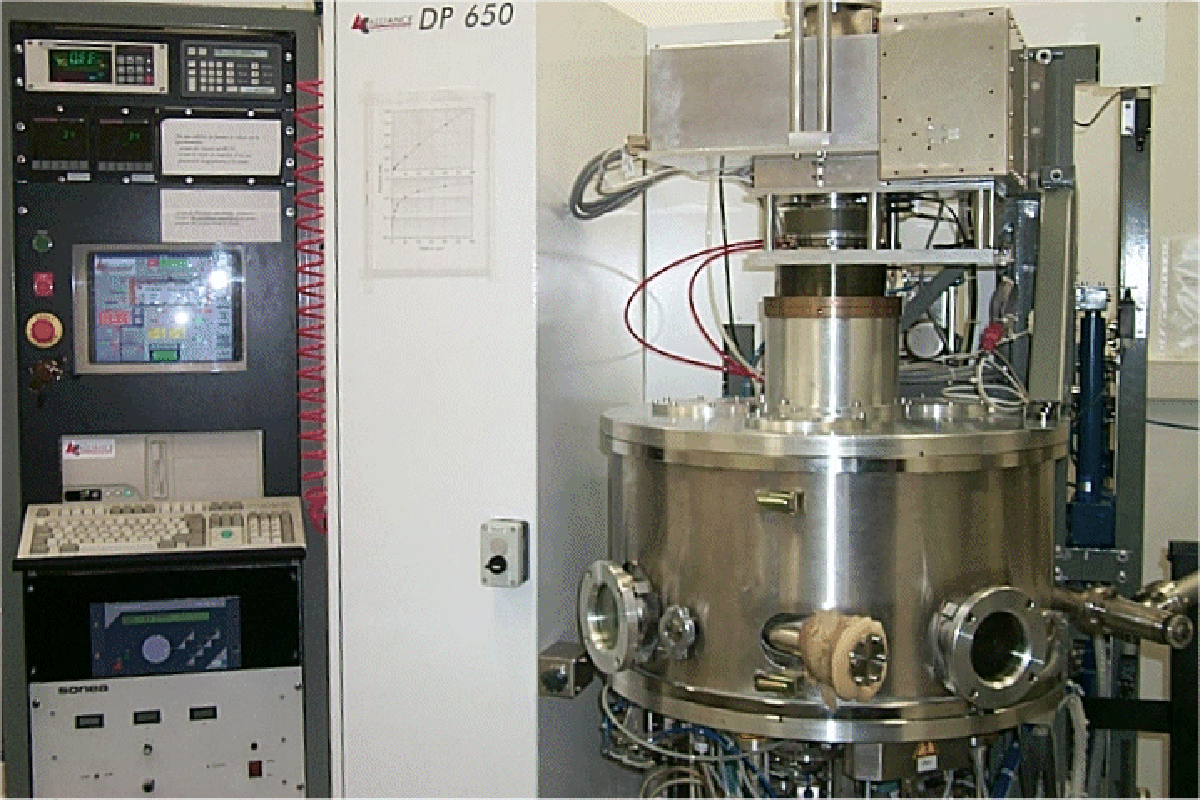

General view of the sputtering machine:

- left: electronics set-up with power supply at the bottom, piloting computer in the middle, vacuum pressure gauge and temperature measurements on top.

- right: the vacuum chamber with on the top the rotation mechanics and piloting as well as the temperature control, below the magnetron power supply connections, on both sides the windows and on the right the gas capture for the quadupole analysis.

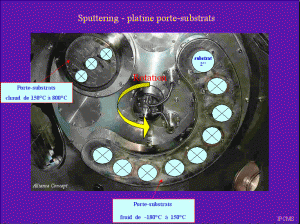

Sample-holder:

Depending on the chimney size, it is possible to prepare within a single run (the deposits are successive, but there is a single pumping run – one night is needed to attain 2 10-9torr):

- 2 to 3 samples on the high-T sample holder

- 7 to 9 samples on the low-T sample holder

Sample-holder from underneath

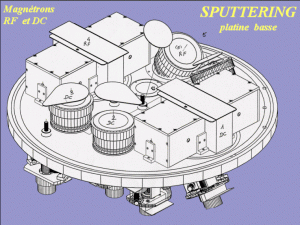

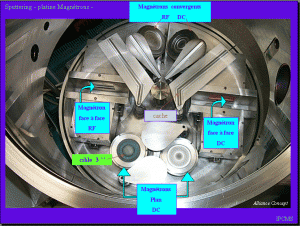

Targets in 3D :

- 2 targets are on horizontal magnetrons (C2 and C3)

- 2×2 targets are on magnetrons in face to face geometry (C1 and C4 – allow to deposit alloys with the same concentration as the targets)

- 2 targets on convergent magnetrons (allow to co-deposit alloys with variable concentration)

Targets (3D scheme)

Targets:

- 2 targets are on horizontal magnetrons (C2 and C3: bottom of the figure)

- 2×2 targets are on magnetrons in face to face geometry (C1 and C4 – allow to deposit alloys with the same concentration as the target: on both sides of the figure)

- 2 targets on convergent magnetrons (allow to co-deposit alloys with variable concentration – top of the figure)

The targets in top view

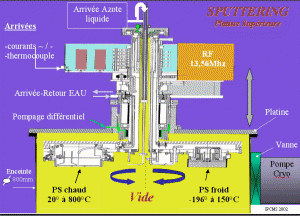

Cross-section:

- sample-holder,

- rotation mechanics,

- cooling with a flow of liquid nitrogen,

- heating…

Cross-section of the top of the vacuum chamber

Contact :