To the development of magnetic nanostructures for spintronics

The use of electron spin in devices is one of the challenges of micro -nano- electronics tomorrow. A lot of work has been devoted to achieving dedicated to spin injection from a ferromagnetic metal into a semiconductor device . The problems come from (i ) the difficulty to achieve steep ( ii) metal / semiconductor interfaces most fundamental barriers to disagree conduction channels of the ferromagnetic metal and semiconductor. An alternative method is to use magnetic semiconductors as the semiconductor diluted type II -VI and III -V , but also semiconductors such as ZnO and GaN doped with Co or Mn . A new type of hybrid nanostructures consisting separated by insulating or semiconducting organic species ferromagnetic metals is the basis of organic spintronics. However much work is needed to control the growth of these artificial structures , obtaining good quality materials , with reproducible magnetic properties ( coupling between separated organic layer ferromagnetic layers ) and finally to understand the phenomena of spin-dependent transport to be able to achieve these artificial structures hybrids DMONS Group IPCMS did the project and put into service , under the supervision of Eric Beaurepaire , a set of deposition chambers under UHV capable of performing a sequence of layers thin :

Metal monocrystalline structure and controlled thickness

- Oxides and nitrides by reactive sputtering

- Organic compounds by evaporation under UHV ( Ombe )

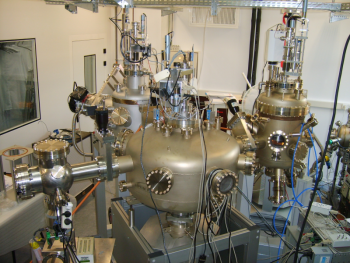

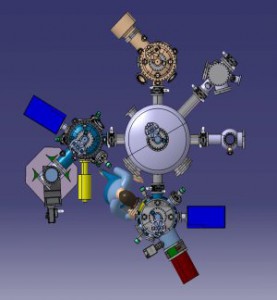

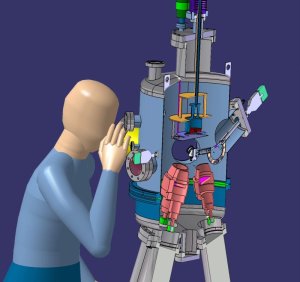

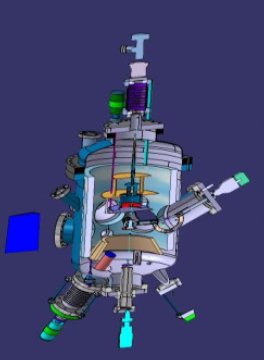

Three deposition methods are not compatible , every step of the manufacturing of hybrid layers must be performed in a dedicated enclosure. Under ultrahigh vacuum transfer between different rooms is imperative to ensure good quality of the interface and fundamental to the material properties . All transfers between 5 bedrooms ( sputtering evaporator Ombe , load locks and soon STM / AFM driver) is provided by a radial distribution chamber UHV , robotic .

Developments are underway to enable the realization of simple devices by deposition through submillimeter masks. Materials developed in the ” hybrid system ” as a basis for the manufacture of magnetic nanostructures, Mageto – Optical and models for organic spintronics devices by the means of micro and nanofabrication IPCMS ( cleanroom , e -fab , Ionic etching) .

A versatile ensemble for the development of hybrid artificial structures :

The steps of epitaxial deposit of ferromagnetic layers of oxide or nitride layers , organic compounds must be performed in rooms Loudspeaker Management Systems to garanir quality dopôts and especially interfaces. The transfer system under UHV MBE between the cathode sputtering Ombe and ensures good quality interfaces.

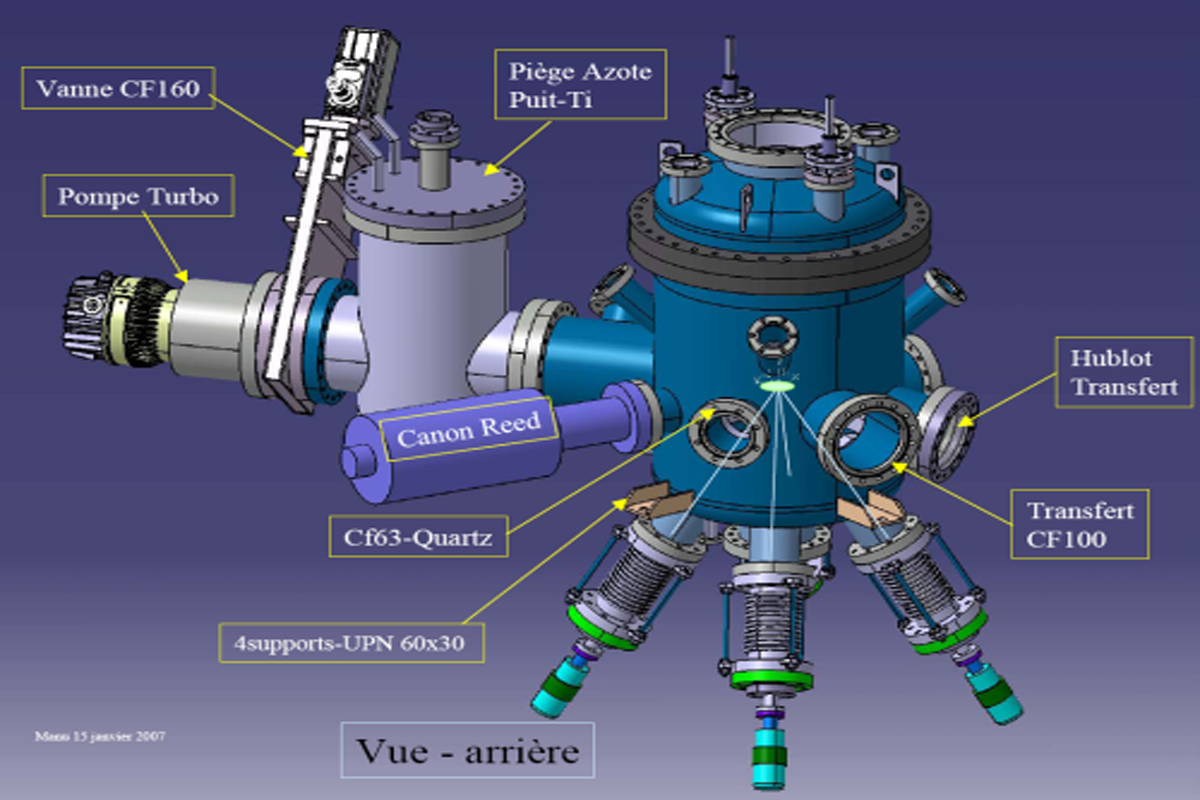

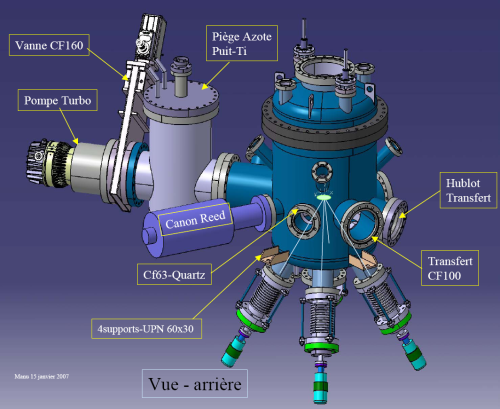

1 Bedroom sputtering under UHV . :

Objective: To understand the development of simple metals and magnetic alloys (Co, Fe , Ni, permalloy ) and reproducible thin film dielectrics, which is well controlled development , as well as magnetic and structural properties (especially oxides and nitrides ) . We then examine more complex systems : Fe3O4 , semi-metal (already developed IPCMS ) in order to optimize the spin injection into the organic semiconductor ; ZnO : Co , semiconductor magnetic relatively transparent in some regions of the optical spectrum , which allows to use as the luminescence sensor and the injection of the spin polarization of the electron orbitals .

Sample holder 2 ” turning T max = 900 ° C , T = 800 ° C under O2 turbomolecular pumping 700l / s , dry pump TriScroll 15m3 Assisted Deposition a source ionsmulticouches4

- 3 reclining magnetrons ( door position ech ) gas supply ( Ar ) through the cell ( ignition ) or directly into the enclosure ( O2 , N2 )

- Magnets without contact with water (life )

- Form of variable magnetic fields ” balanced / unbalanced “

- RF , DC, pulsed DC power .

In a DC portion of the target is covered with an insulating compound which causes an accumulation of positive charge during the ion bombardment causing electric shock . This is a source of inhomogeneity of the deposition , defects in the layer and plasma instability . The pulsed DC between 2 – 100kHz is a solution recommended for ITO , SiO2, Al2O3, Zr02 . Expected effects : increased reactivity of the plasma , the greater density of the layer stoichiometry observed when co – deposition .

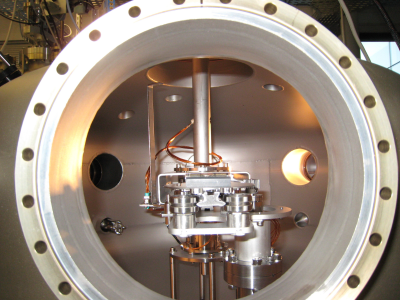

2 Evaporator UHV manipulator with masks Objective.:

- Achieving growth of mono crystalline metal thin films.

- Making millimeter-scale devices by deposition through masks

Sample holder 2 “-150 ° C / 600 ° C

30kV RHEED

Quartz balance

4 high temperature cells regulated to 0.1 ° C

Manipulator masks, precision 5microns.

Turbomolecular pump 240l / s,

Ion pump 400l / s, Ti enhancer

Cryogenic pumping (L N2)

3 . Molecular Beam Epitaxy Organic

objectives:

(Long term) explore the potential of organic materials in the field of spintronics , optics and materials for organic photovoltaic effect .

( Short term) Making a completely molecular jet magnetoresistive device model , composed of electrodes separated by a ferromagnetic metal thin film organic -based molecules \ pi conjugated polycyclic aromatics such perylenes ( PTCDA ) or phthalocyanines (Pc ) .

Sample holder 2 ” T max = 500 ° C

20kV RHEED

Quartz balance

The Ombe is an essential tool for making metal heterostructures ferromagnetic / organic / ferromagnetic metal which is controlled morphological properties (flatness ) , structural ( crystalline order , interdiffusion ) and electronic ( charge transfer at interfaces ) . The particular interest of the family of molecules that we want to use ( pthalocyanines ) lies in the diversity of substitution and hence properties it has, for example to explore the effect on the magnetotransport properties of the nature of charge carriers (electrons or holes or F16CuPc CuPc ) , spin -orbit coupling or local magnetism for the classical- organic compounds ( FFDM , … PBPC ) .

4. Robot radial distribution:

Robot radial distribution, provides transfers from molyblock 2 “under UHV between sas (warehouse in development) and three deposition chambers. Telescopic arm is rotated and translationally integrated in engine UHV. It works in manual, semi-auto (racket remote control) and automatic (computer). This robot allows the provision of rooms in star, economical solution for installing the integrated system in a ski reduced dimensions.

A fifth bride is waiting for an extension to the UHV AFM conductor.

Contact :