Booking System :

Lithography :

UV Lithography

- writemode I 2 mm with 0.7 µm resolution (write field 3″)

- writemode II 4 mm with 1 µm resolution (write field 4″)

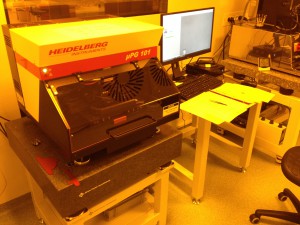

Heidelberg µpg101 Laser Writer

The Heidelberg µPG101 is a direct writing lithography (DWL) system with two writing modes

- chromium mask or soft plastic film up to 4″

- microscope objectives : X10 et X20

Süss MJB3 mask aligner

MJB3 mask aligner is dedicated to lab work (master students) and to the processes based on SU8 resist (ex. microfluidic). Key features

Different contact modes are available :

- proximity

- soft contact

- hard contact

- vacuum chamber

Süss MJB4 mask aligner

MJB4 mask aligner handle 4″ and 5″ masks. The size of the sample goes from 10×10 mm² up to 4″. The precision of the alignment is ±1µm and the microscope (linked to a camera) is equipped with x10 and x20 objective lenses.

Ebeam Lithography

key features :

- Schottky Thermal field emission type

- Gemini Column

- Resolution: 1 nm at 20 keV

- working distance: 2 mm

- Acceleration voltage: 0,1 to 30 keV

- Probe current: 20 pA à 20 nA

- Stage repeatability: 1 µm

- pattern generator: 6 MHz / 16 bits

Zeiss Supra 40 + Raith elphy plus

Ebeam lithography is composed by a Zeiss Supra 40 FESEM coupled with Raith Elphy Plus software.

Thin Films :

Evaporation

The planetary sample holder is able to tilt from 0° to 270 ° and/or rotate during deposition.

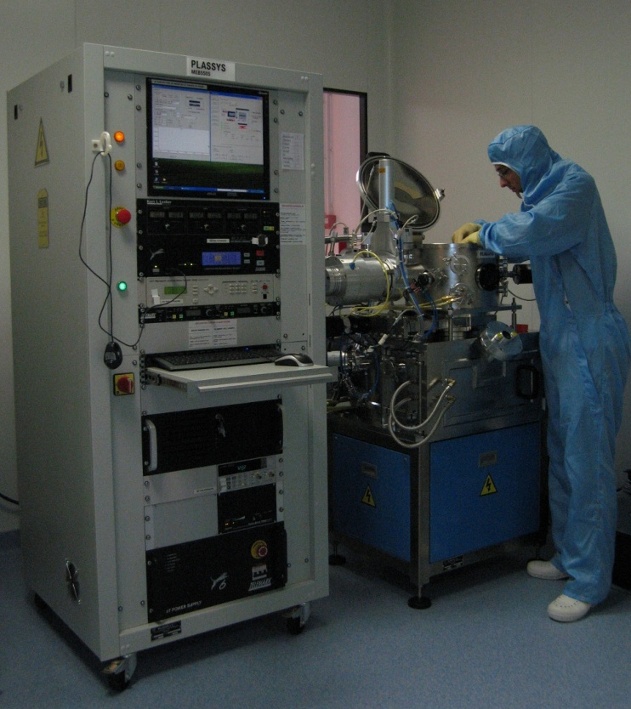

Plassys MEB550S

E-beam evaporator for metallic thin films (Al, Au, Co, Cr, Ni, NiFe, Ti).

The load-lock is equipped with an argon ion gun for cleaning the samples.

The sample holder can be cool down with liquid nitrogen (77K) and tilted (0 – 90°)

Plassys MEB 300

Thermal Evaporator for metallic thin films (Cr, Al, Au, Ag).

Sputtering

The sample can be heated up to 250°C with an halogen lamp

Plassys MEB 400

E-beam Evaporator for non standard deposition (ex. CoFe).

The system is equipped with an ion gun (Ar, O2).

Edwards Auto 306

Thermal Evaporator for exotic materials (metal, organic)

Alliance Concept EVA300+

Sputtering system with 3″ RF & DC magnetrons)

Targets : ITO, SiO2, Si3N4, Si

gases : Ar, N2, O2

size of subtrate: up to 4

Etching :

Dry Etching

key features :

- back side Helium cooling (thermal contact)

- laser interferometry

- size of sample up to 100 mm

Reactive Ion Etching

Plasmalab 80 plus (OIPT) : Reactive Ion Etching system with ICP source (RIE-ICP).

Etched materials: Si, Si3N4, SiO2, Quartz, Polymers

Gaz disponibles : Ar, He, CHF3, SF6, O2, CF4

Wet Etching

- Hydrofluoric Acid (HF)

- SiO2 etching

- Piranha: sulfuric acid (H2SO4) + hydrogen peroxide ( H2O2)

- mask cleaning

Acid Etching

(Ask a staff member for these processes)

Back end :

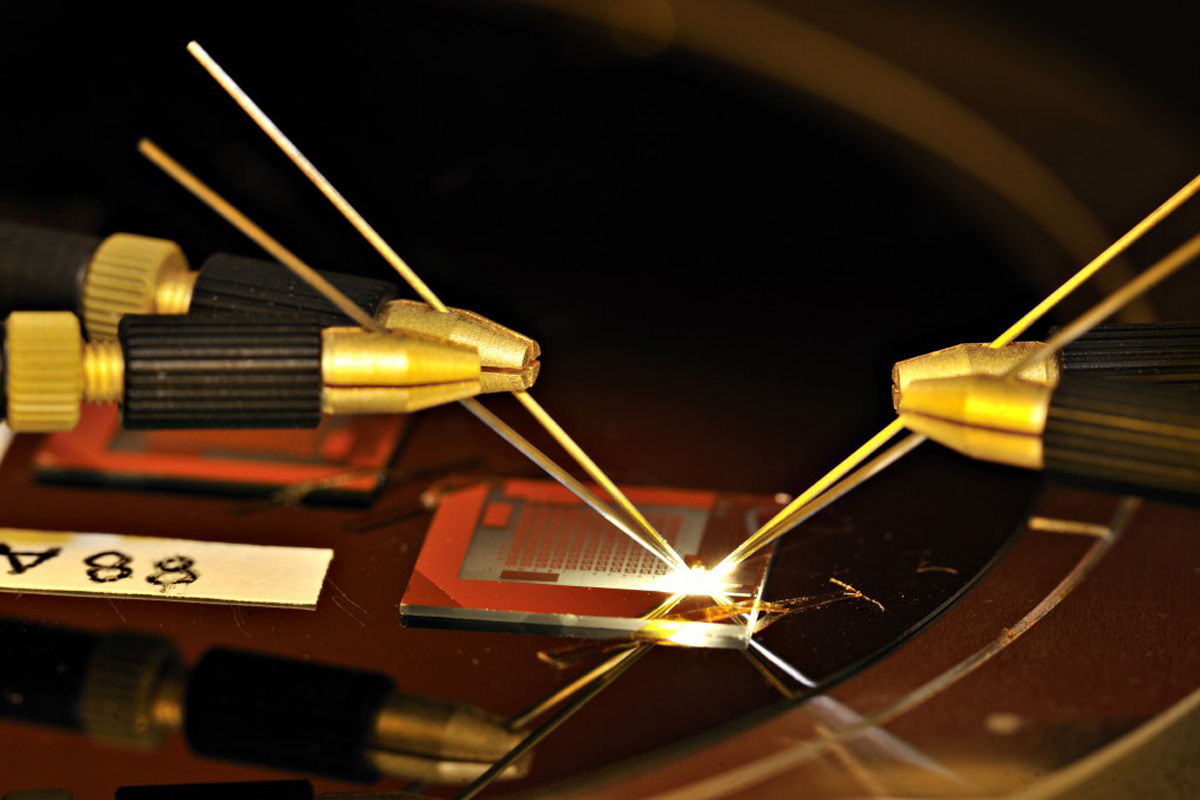

Wire bonding

Hybond 626 semi-automatic gold wire bonder (wedge and ball bonding).

Scriber

Scriber for silicon wafers

Wafer dicing Machine

Semi-automatic Dicer MachineAcretech SS10 ModelSuitable for various types of materials and dimensions

Characterization :

- C-AFM : Conductive AFM

- PFM : Piezoreponse

- MFM : Magnetic Force Microscope

- nanolitho

Atomic Force Microscopy (AFM)

Atomic Force Microscope (Bruker Dimension Edge)..

Optical Microscopy

Different microscopes are available to users for qualitative monitoring processes (like the Zeiss Axio Imager microscope equipped with a X100 lens)

Profilometer

The 3D Dektak mechanical profilometer (Veeco) can handle up to 6″ substrates. The stage is motorized one can make 3D mapping of the samples.

4 Probes Station

arl Suss PM8 Probe Station (linked to a Keithley 2400 sourcemeter and Keithley 2100 digital multimeter). There’s also a Sheet Resistance Meter with Four Point Probe (Lucas Labs 302)

Microfluidic Lab :

At STnano, we have a microfluidic lab. This dedicated area is equipped to realize PDMS replica on SU-8 mold. In this room one can find :

- a weigh and different tools

- a vacuum oven for PDMS degassing

- a plasma for surface activation

- a microscope to align the replica and the sample before sticking