The frame of the ion beam etching is one way of developing magnetic nanostructures IPCMS GEM (see also the cleanroom and e -fab ) .

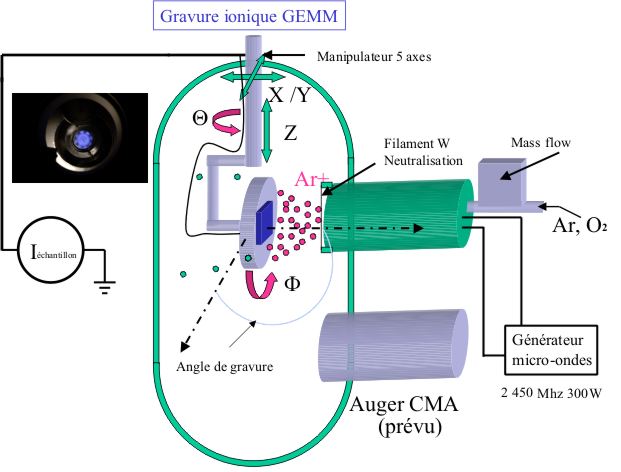

Fitted with a microwave plasma source of 300 W , 2.45 GHz , this source of 50 mm diameter is fed with Ar and O2 via a mass flow controller such flow. The ion energy is 200 to 500 eV . The etch rate is of the order of 10 nm / min to metals and resins , slower for dielectric . The ion beam may be neutralized by an electron source filament W. The sample 2 ” maximum , fixed on a molyblock is transferred from the load lock to a receptacle placed at the end 5 of the manipulator axes . Angle engraving is adjustable from 0 to 90 ° , the permanent sample rotation around its axis ensures the homogeneity of the engraving. pressure in the bed is controlled by a gauge ” + Pirani Penning .” vacuum basic 5 x 10-9 Torr .

Detecting etch end is currently done by the calibration etch rate on control samples. To this reliable technological step , we wish to acquire a CMA Auger spectrometer types .

Research topics:

- Hybrid Spintronics

- Electroresistance

- Junctions magneto-resistive scale of the atom

- Doppler shift of spin waves

- Spin-polarized transport through new multifunctional oxides

- Organization and addressing molecules magnets

- Nanostructured alloys anisotropic layers

- Influence of nanotopography on the organization of biological cells and proteins (ISCI)

- New nanostructures for electrocatalysis (ECPM)

Ion etching is available provided initial training and booking. The manual is available on the internal website

Contact :